-

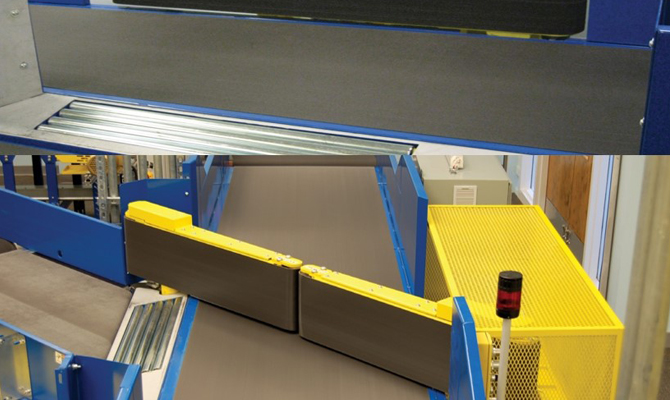

Including single arm and double arm diverter

Including single arm and double arm diverterSingle arm diverter

• Its function is remove the baggages from one conveyor to the adjacent conveyor or the carousel during the system of BHS• Its efficiency is up to 20 baggages /mins

Double arm diverter

• The double arm will remove the bagages from one conveyor to the adjacent one correctly during the high flow capacity , which can also sort the baggages from the major conveyor to the vertical conveyor or the with angle of 45 .

• The diverter arms of the two robust operational belts will play the diverting role on the baggages from the crosswise• It will not undermine the baggages during the high speed operation .• Its efficiency is 30 baggages /mins

HORIZENTAL DEVERTER -

Including :standard weighting / stigma conveyor and transion conveyor

• Modular ,safety , reliability , and fasion design• Made of stainless steel• Diamond -type belt surface• With horizontal and tilt conveyor for option• The wheel structure is easy to move when repaired or maintained• Check-in model with working plaform for option.Air cargo handling system -

Including:standard weighting / stigma conveyor and transion conveyor

• Modular ,safety , reliability , and fasiondesign• Made of stainless steel• Diamond -type belt surface• With horizontal and tilt conveyorfor option• The wheel structure is easy to movewhen repaired or maintained• Check-in model with working plaformfor option.Check-in conveyor -

Take away conveyor is one part of major transport line , which is used for collecting and taking away the baggages that come from each check-in transport line after security check .

Take away conveyor is consists of rack , belt ,fender apron and driving and control equipment . for easy manufacturing , transportation and installation , which is seperated into segments self-independently . Both sides of the equipment installed with fender aprons and exposed side guide plates , within the passenger's visual area , all of the them are made of stainless steel materials(SUS304) .

The take away belt tensioning devices are installed on the back side of the belt , make adjustment of handlebar of the screwrod and installed on both sides of the rack, not the center , easy for adjustment . Further to move the received baggages in a strict manner , nonoccurrence of baggage malposition ,clashes , conjuction and overlap . with shock resist installed , the adjacent belt fender apron installed in order , smooth , ensure the regular operation of the baggages .

Take away conveyor -

Thequeueing conveyor is a short conveyor designed to queue , index or separatebaggages whenever required before conveyor junction , X-RAYS machine in a system .

• Modular ,standalone , robust and reliable• Designed for frequent start /stop operation• Low cost to mainteance• Low noise• Standardor custom designed , flexibly adjustedof length , slope , or downtrendQueue conveyor -

The vertical diverter is the regular sorting machine , which will be used to deliver the baggages or package between the two diverters which are not in the same horizental level without vibration and in low noise and smoothly .The vertical diverter can be categorized into single arm and triple arms , comparing the horizental diverter , which will reduce the friction of the baggages during the operation .

The efficiency of triple arms diverter is over 30 units of baggages /mins

The framework and modular design adopted by Pteris , which will be prevented the transformation during the high efficiency switch of the vertical diverter .in the meantime , which can be compatible to the structure and driving unit of all the diverters

Vertical splitter